In today’s hyperconnected economy, logistics is no longer just about moving goods from point A to point B — it’s about precision, visibility, and real-time decision-making.

The Internet of Things (IoT) is at the heart of this transformation. By embedding sensors, trackers, and smart devices across supply chains, IoT is enabling businesses to monitor assets in motion, predict disruptions before they happen, and optimize operations down to the last mile. From fleet management to cold chain monitoring, IoT technologies are driving a new era of transparency, efficiency, and agility in logistics.

As global supply chains face increasing pressure from market volatility and customer demands, investing in IoT is no longer optional — it’s a strategic imperative for forward-thinking logistics providers.

- IoT is a strategic enabler for logistics in 2025, offering real-time visibility and automation.

- Smart logistics solutions powered by IoT drive sustainability, safety, and customer satisfaction.

- Future trends point toward deeper integrations with AI, 5G, blockchain, and autonomous systems.

What is IoT?

IoT (Internet of Things) refers to a network of interconnected physical devices — such as sensors, RFID tags, GPS trackers, and smart meters — that collect and transmit data over the internet. These devices allow organizations to monitor conditions, track movements, and trigger automated actions without human intervention.

In logistics, this means full transparency into where shipments are, how they’re handled, and what condition they’re in — all in real time. From fleet management and route optimization to cold chain monitoring and predictive maintenance, IoT helps logistics businesses work faster, smarter, and with fewer disruptions.

As global supply chains face increasing pressure from market volatility and rising customer expectations, investing in IoT is no longer optional — it’s a strategic imperative for forward-thinking logistics providers.

Key Challenges Facing the Logistics Sector

Before diving into the benefits, it’s essential to understand what’s at stake. Modern logistics companies are grappling with several persistent challenges:

- High Demand and Pressure for Speed: E-commerce growth requires real-time tracking and next-day delivery capabilities.

- Limited Visibility: Manual tracking leads to delays, lost cargo, and inefficiencies.

- Unexpected Equipment Failures: Unscheduled vehicle downtime can disrupt the entire supply chain.

- Storage Conditions: Many products require precise temperature and humidity control during transport.

- Sustainability Regulations: Ground transport is a major source of CO₂ emissions, with growing pressure for greener logistics.

- Manual Inventory Management: Traditional warehouses still rely on outdated processes and human input.

- Security and Data Fragmentation: As logistics becomes digital, protecting sensitive cargo data is more complex than ever.

11 Powerful Ways IoT Is Transforming Logistics in 2025

Unlock the Future of Logistics with IoT — Partner with Ficus Technologies Today!

Contact us- Real-Time Cargo Tracking

With GPS-enabled IoT sensors, logistics teams can monitor the exact location of goods in transit. This ensures accurate ETAs, reduces lost shipments, and allows customers to track their orders live.

Key Benefit: Enhanced transparency and reduced delivery anxiety for end users.

- Predictive Maintenance of Vehicles

IoT sensors embedded in trucks monitor engine performance, oil levels, tire pressure, and more. Predictive analytics flag maintenance issues before breakdowns occur, reducing costly disruptions.

Key Benefit: Lower maintenance costs and fewer unexpected delays.

- Smarter Route Optimization

IoT systems connect with traffic data and fleet systems to adjust routes in real-time based on congestion, weather, or road closures.

Key Benefit: Faster delivery times and lower fuel consumption.

- Condition Monitoring of Sensitive Goods

Cold chain logistics benefits from IoT devices that track temperature, humidity, tilt, and light exposure in real time. Alerts notify teams of any violations.

Key Benefit: Fewer spoilages and compliance with health and safety standards.

- Autonomous Inventory Systems

RFID tags, smart shelves, and vision-based sensors reduce human error in warehouse management. Inventory levels update automatically, and stock shortages or overstocking are minimized.

Key Benefit: Optimized stock levels and lower labor costs.

- Enhanced Worker and Driver Safety

Wearable IoT devices track driver fatigue, heart rate, or erratic movements, helping prevent accidents. Geofencing features also alert teams to unauthorized stops or off-route deviations.

Key Benefit: Reduced risk of injuries and increased fleet accountability.

- Reduced Fuel and Energy Waste

IoT analytics identify inefficient driving behavior and excessive idling. Fleet managers receive recommendations on how to reduce fuel use across the board.

Key Benefit: Lower operating costs and a smaller carbon footprint.

- Streamlined Loading and Unloading

IoT-enabled scanners and RFID-based systems automate parcel identification and sortation. Forklift routing becomes more efficient with real-time dock updates.

Key Benefit: Faster warehouse turnover and improved asset utilization.

- Improved Forecasting and Demand Planning

Sensor data feeds into analytics platforms that predict seasonal demand spikes and bottlenecks. This helps logistics companies adjust resources and staffing in advance.

Key Benefit: Better decision-making and fewer costly surprises.

- Increased Shipment Security

IoT locks, motion sensors, and surveillance integrations help track if a shipment is tampered with or diverted. Smart alerts notify security teams instantly.

Key Benefit: Stronger cargo protection and loss prevention.

- Sustainable Logistics Practices

IoT-powered emissions monitoring enables companies to audit and reduce their environmental impact. Smart containers can even adjust internal temperatures to optimize energy usage.

Key Benefit: Progress toward green logistics goals and regulatory compliance.

Real-World Use Cases

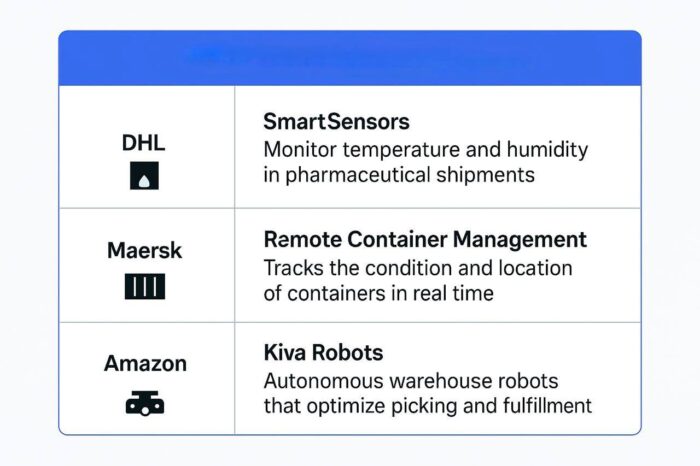

The impact of IoT in logistics is not theoretical — leading companies are already demonstrating how connected technologies transform supply chains.

DHL’s SmartSensors are redefining pharmaceutical logistics. By embedding temperature and humidity sensors into shipments, DHL can continuously monitor environmental conditions during transport. If deviations occur, alerts are triggered instantly, enabling corrective action before products are compromised. This approach has dramatically reduced spoilage, improved regulatory compliance, and strengthened trust among healthcare providers.

Maersk’s Remote Container Management (RCM) system illustrates how IoT enables visibility on a global scale. Equipped with smart devices, Maersk containers transmit data on location, temperature, and CO₂ levels in real time. Customers can track cargo conditions throughout the journey, while Maersk uses predictive insights to optimize routing and minimize delays. The result is greater transparency, operational efficiency, and improved customer satisfaction.

Amazon’s Kiva Robots show the power of IoT in warehouse automation. These autonomous robots navigate vast storage facilities, locating and transporting items with precision. Coordinated by a central system, they reduce picking times, cut operational costs, and enable faster order fulfillment. This IoT-powered automation has set new standards for e-commerce efficiency and scalability.

Beyond these high-profile examples, many logistics providers are using IoT to support sustainability initiatives. By combining emissions monitoring with predictive analytics, companies are identifying fuel inefficiencies, optimizing vehicle routes, and cutting CO₂ emissions. This demonstrates how IoT is not only about efficiency, but also about building greener, more responsible supply chains.

Together, these cases prove that IoT adoption in logistics is no longer optional. It has become the backbone of real-time visibility, predictive maintenance, automation, and sustainable growth.

The Future of IoT in Logistics

The next stage of IoT in logistics will be defined by deeper integration with other transformative technologies. Artificial intelligence will unlock advanced predictive analytics, allowing companies to anticipate disruptions, optimize demand planning, and automate operational decisions with greater accuracy.

The expansion of high-speed networks will make large-scale IoT deployments more reliable, enabling real-time communication between fleets, warehouses, and ports. Blockchain will bring a new level of trust to logistics by securing data transactions and providing transparent, verifiable cargo records.

At the same time, robotic automation — including autonomous drones, driverless vehicles, and warehouse robotics — will depend on IoT as the connective layer that synchronizes machines, sensors, and control systems.

While concerns around cybersecurity and initial investment remain, the direction is clear: IoT is evolving from an efficiency tool into the backbone of supply chain resilience, sustainability, and competitiveness.

Conclusion

The Internet of Things is more than an upgrade to logistics — it is a reinvention of the industry. By 2025, connected devices are enabling real-time cargo visibility, predictive maintenance, autonomous inventory, and sustainable practices that redefine how supply chains operate. Companies that embrace IoT gain the ability to anticipate disruptions, reduce inefficiencies, and deliver a superior customer experience.

The decisive factor in the years ahead will be the ability of logistics providers to integrate IoT into every level of operations. Those who act now will not only cut costs and risks but also build resilient, data-driven supply chains capable of thriving in uncertain markets.

Why Ficus Technologies?

Choosing the right IoT partner is as critical as choosing the right technology. At Ficus Technologies, we combine deep technical expertise with industry knowledge to deliver IoT-powered logistics solutions that generate measurable results.

Our approach includes:

- Custom IoT development — tailored software that integrates sensors, trackers, and real-time analytics.

- End-to-end integration — from warehouse systems to fleet platforms, ensuring full visibility across the supply chain.

- Advanced analytics — AI-powered forecasting, anomaly detection, and predictive insights built into dashboards.

- Security and compliance — robust encryption, access controls, and ISO-certified processes for sensitive cargo data.

- Scalable architecture — solutions that grow with your business, from small fleets to global supply chains.

With more than 12 years of experience in custom software engineering, 70%+ senior-level developers, and a proven track record across logistics, retail, and manufacturing, Ficus Technologies helps companies turn IoT from a buzzword into a strategic advantage. We don’t just connect devices — we connect logistics businesses to the future.

Common devices include GPS trackers, environmental sensors (temperature, humidity), RFID tags, wearables, and predictive maintenance monitors.

IoT security requires robust encryption, access controls, and regular audits. Partnering with experienced IoT developers like Ficus ensures best practices are followed.

It varies. A proof-of-concept can take 4–8 weeks; full-scale rollout may span several months depending on complexity.

Yes. Even mid-sized fleets can benefit from predictive maintenance, route optimization, and real-time tracking without major investment.